Keeping possible contamination sources away from lubricated equipment is the best line of defense against contaminants entering machine parts. It is significantly more difficult and expensive to remove contaminants from the system than it is to modify and protect equipment against ...Continue Reading

Product Knowledge

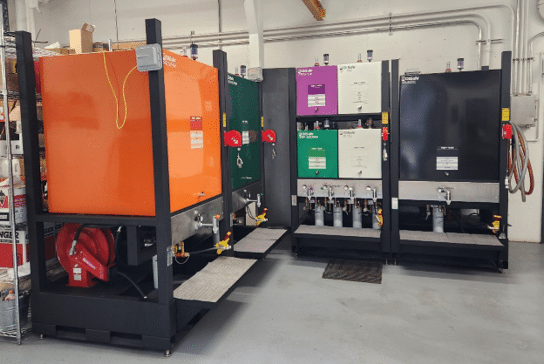

Your lube room is the foundation of your lubrication program and a key driver of equipment reliability. In this webinar, see how Georgia-Pacific’s Toledo plant turned an inefficient space into a best-in-class lube room. Then, OilSafe’s Dean Hammes will walk ...Continue Reading

One of the greatest opportunities I have as a technical consultant is the chance to walk through various plants around the world. I have visited power plants, food-processing plants, refineries, manufacturing facilities and a long list of others. During these ...Continue Reading

These best practices can help your assets perform at peak efficiency. For many companies, lubrication is a required maintenance function that is too often considered a necessary evil or underestimated as a simplistic process. A deep, detailed look at your ...Continue Reading

One of the best ways to care for machine assets is to ensure that the lubricants protecting them are clean, healthy, and ready to perform before they are put into service in our machines. It is common for oil analysis to be ...Continue Reading

Chances are, if you work in an industrial setting, you have someplace where you store lubricants. It might be an old shipping container, a sectioned-off part of a warehouse or even a collection of pallets outside and a few lockers. ...Continue Reading